Wer kann am Besten die tägliche Arbeit verbessern? Natürlich die betroffenen Mitarbeiter.

Neben einer Verbesserung Ihres Produktionsprozesses oder der Stückliste (Stichwörter Kaizen und KVP) sowie einer damit einhergehender Kostensenkung, hat eine Verbesserungskultur durch die Mitarbeiter einen weiteren Vorteil: Es motiviert Ihre Mitarbeiter auch, eigene Vorschläge einbringen zu können und Gehör zu finden.

Auch Odoo ist dieser Meinung und bietet daher die nötigen Funktionen dafür. Gerne beraten wir Sie dazu und implementieren anschließend die Lösung mit Ihnen.

Tauchen Sie mit uns, der Fertigungsmitarbeiterin Maria und ihrem Vorgesetzten Manuel ein in das Modul "Produktlebenszyklus"!

1. Technische Voraussetzungen

Sie brauchen die App Produktlebenszyklus, welche bei Installation Ihr Odoo automatisch um die abhängigen Apps Werkstatt, Fertigung, Lager und Mitarbeiter erweitert. Darüber hinaus sind die folgenden Einstellungen in den Nutzerrechten vorzunehmen:

- Der Mitarbeiter in der Fertigung braucht die Rolle "Administrator" in der Fertigungsapp.

- Der Mitarbeiter in der Fertigung braucht die Rolle "Benutzer" für die App Produktlebenszyklus / Product Lifecycle Management (PLM).

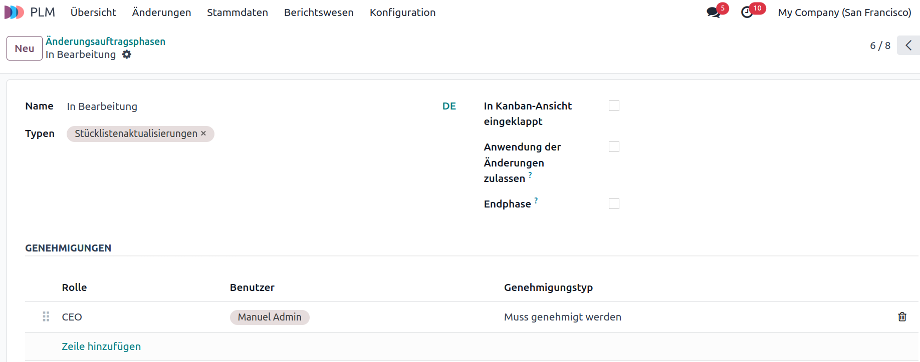

- Jemand mit "PLM: Admin" Rechten hat die Stufen von Änderungsvorschlägen bereits korrekt konfiguriert. In unserem Fall bedeutet das, es wurde hinterlegt, dass die Umsetzung einer Änderung in der Fertigung die Genehmigung durch den Vorgesetzten benötigt und nicht einfach selbständig durch Maria erfolgen kann:

2. Rückmeldung aus der Sicht von Maria in der Produktion

Maria: Ich fertige Tische an und schraube im Rahmen dessen die Tischbeine mit Winkeln an den Tisch. Zudem fixiere ich für mehr Stabilität einen Rahmen unten an den Tisch. Diesen Rahmen schraube ich mit einem Imbus fest, da er mit Innensechskantschrauben gehalten wird. Die Tischbeine hingegen mit Kreuzschrauben. Es kostet mich jedes Mal Zeit, das Werkzeug zu wechseln und eigentlich könnten wir uns eines der Werkzeuge sogar ganz sparen, wenn wir dieselben Schrauben benutzen würden. In Odoo kann ich diese Idee ganz einfach weitergeben an die Arbeitsvorbereitung bzw. den Produktionsleiter.

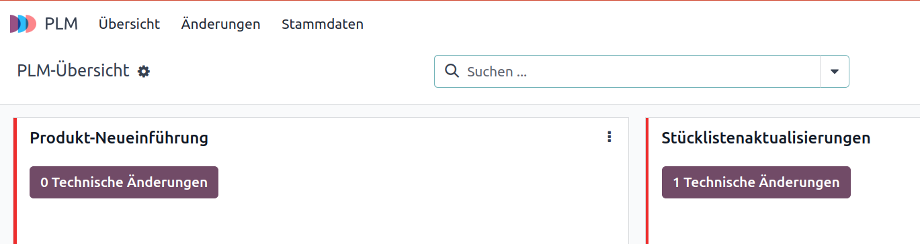

Dazu gehen wir in die App "PLM" und folgen dem Link zu Stücklistenaktualisierungen.

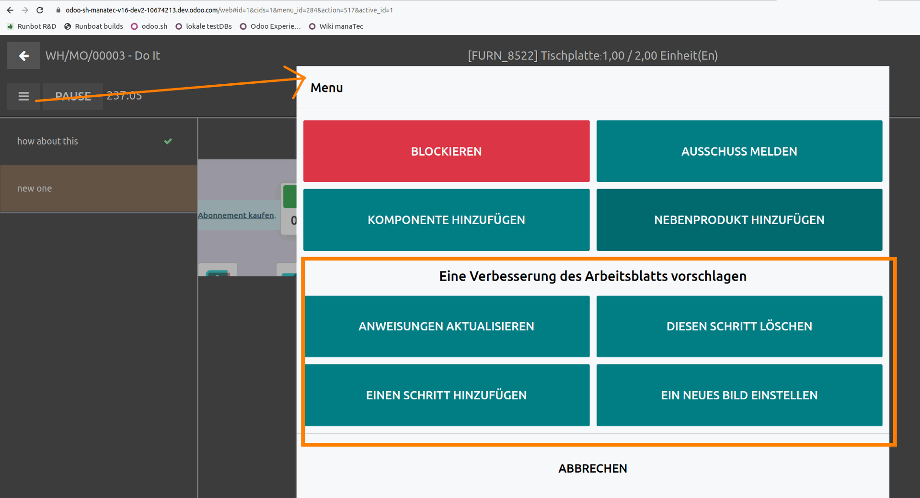

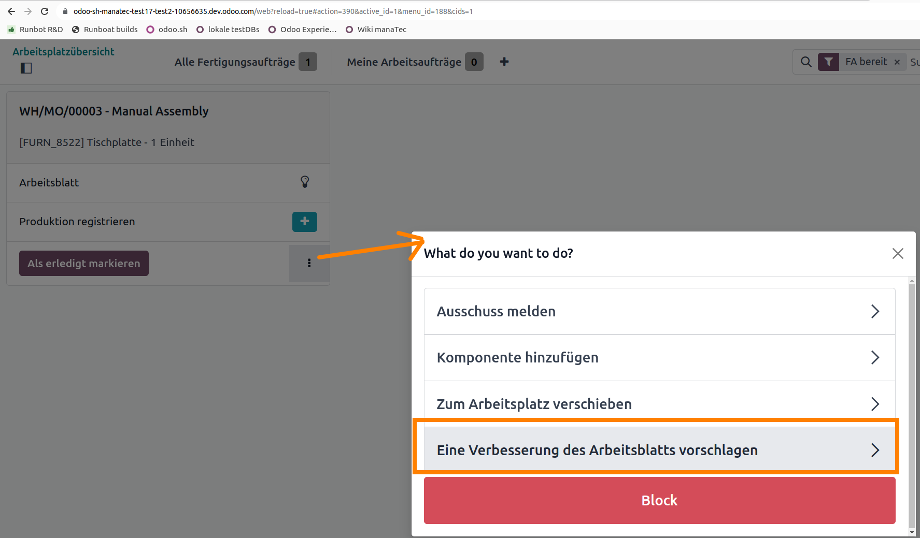

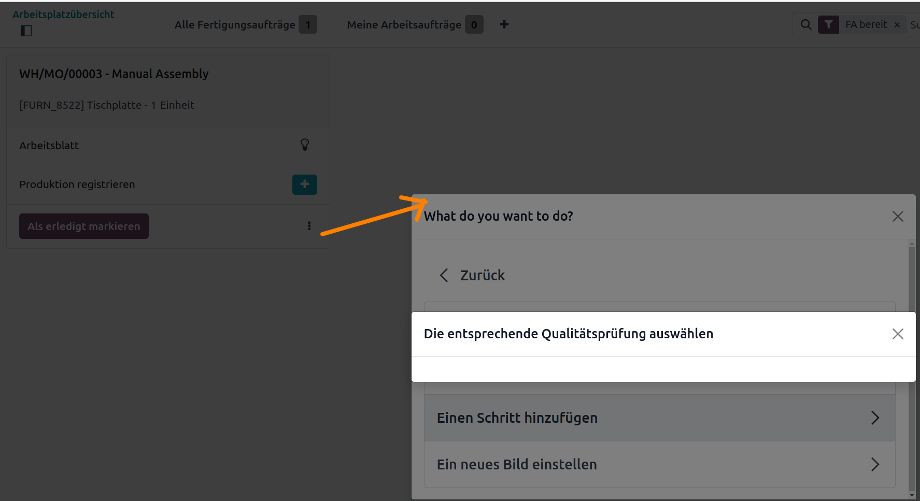

Alternativ direkt aus der App "Fertigung" in der Tabletansicht (V16) oder aus der App "Werkstatt" (V17). Seit Odoo 17 setzt dies voraus, dass auch die App "Qualität" installiert ist, da diese die Arbeitsschritte stellt.

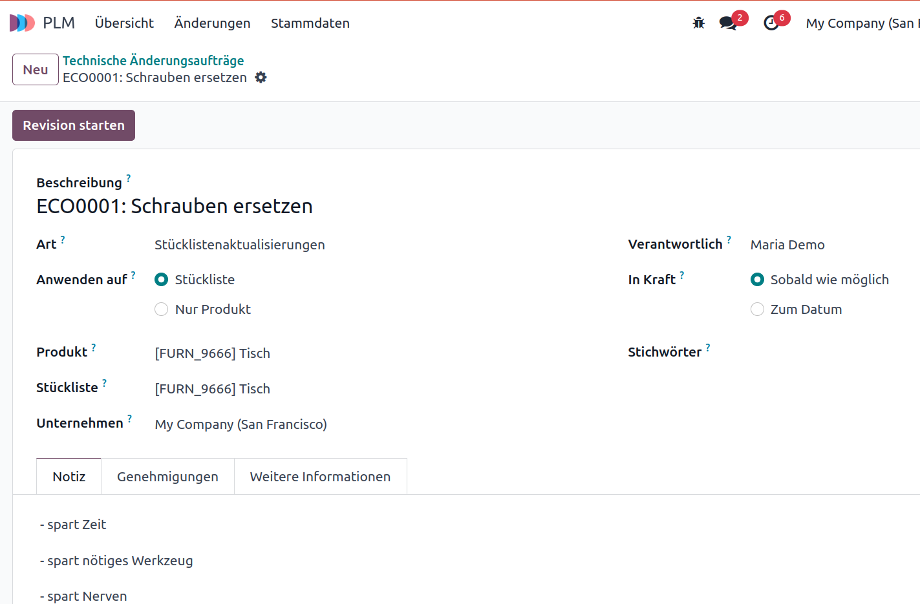

In unserem Beispiel gehen wir über das Modul "PLM", wählen die entsprechende Stückliste und starten die Revision:

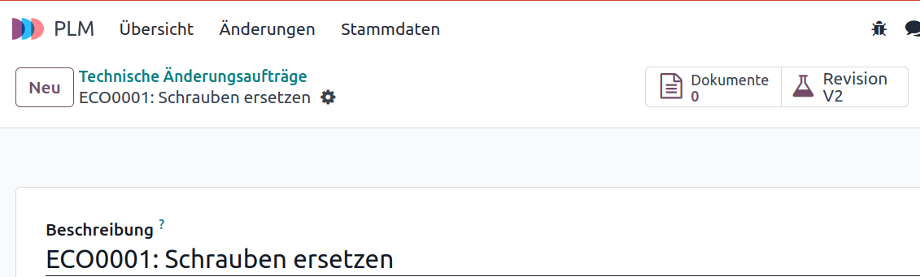

Über den Smartbutton kommen wir in die neue Revision V2:

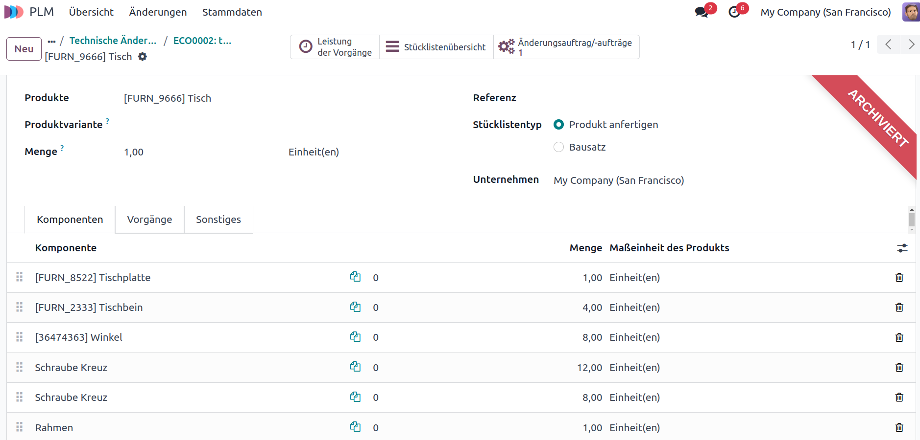

Wir kommen auf eine derzeit noch archivierte Stückliste, wo wir die Teile ändern, so wie wir es für sinnvoller erachten. In unserem Fall entfernen wir die Innensechskantschrauben und fügen stattdessen 8 weitere Kreuzschrauben zu den bereits existierenden 12 Stück hinzu oder notieren auf der Liste einfach statt 8 Innensechskant nun 8 weitere Kreuzschrauben:

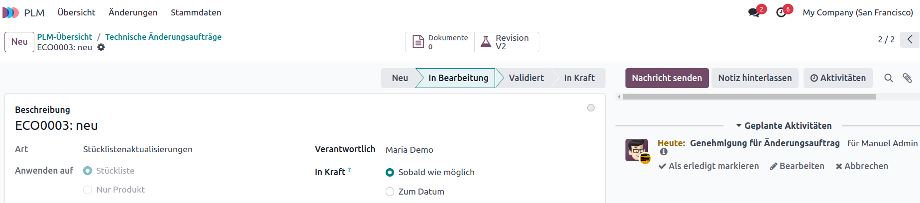

Danach setzen wir den Änderungsvorschlag auf "In Bearbeitung" weiter und der Vorgesetzte erhält automatisch eine Aktivität, dass er genehmigen oder ablehnen soll:

3. Schritte aus Sicht des Vorgesetzten

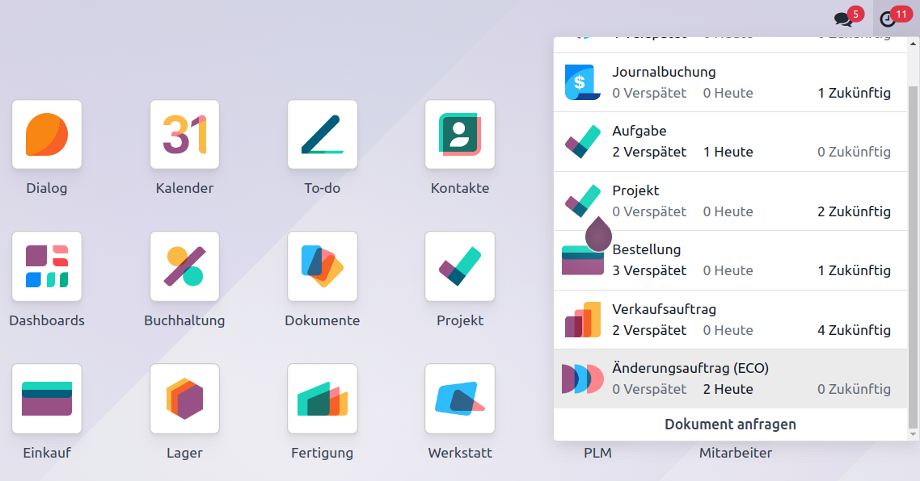

Wir haben nun eine Aktivität für PLM erhalten:

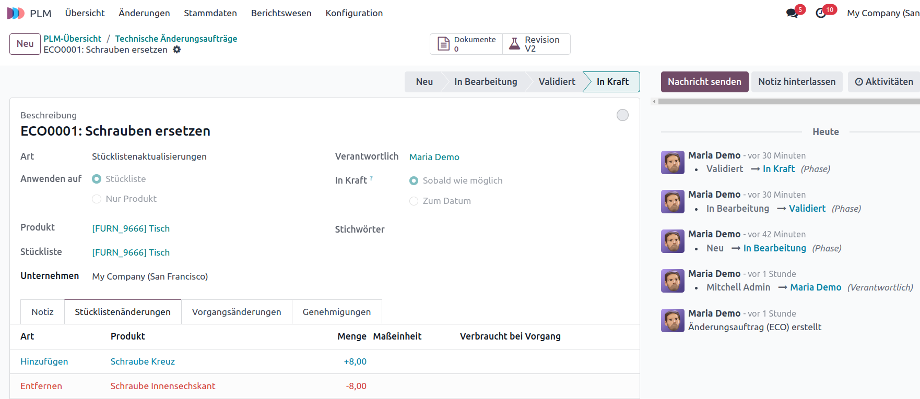

Wir sehen, was zur Änderung vorgeschlagen wurde und können diese genehmigen oder ablehnen. Nach Genehmigung müssen wir die Mitarbeiterin informieren und sie kann den Prozess dann fortsetzen. Fragen Sie uns hier gerne nach einer Automatisierung dieses Schrittes.

Sobald die neue Stückliste in Kraft tritt, archiviert Odoo nun die vorherige und dearchiviert die neue Stückliste, womit sie gültig wird. Alle Änderungen sind nachvollziehbar in dem technischen Änderungsauftrag über den Reiter “Stücklistenänderungen”:

4. Besonderheit bei mehreren Änderungsaufträgen gleichzeitig

Odoo denkt mit und hat vorgesorgt für den Fall, dass mehrere Änderungen für eine Stückliste gleichzeitig in Kraft treten und die Stückliste somit durcheinanderbringen würden:

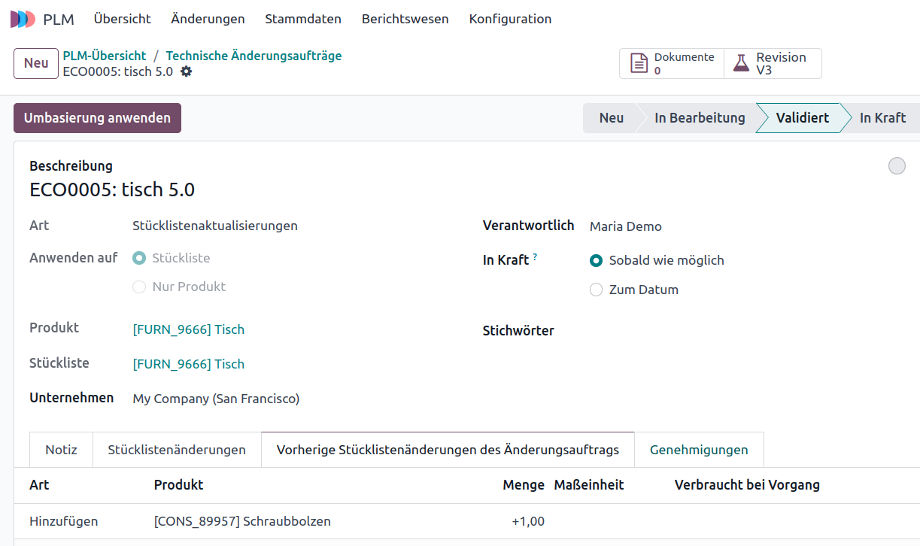

Die neue Stückliste, die als erstes bewilligt wird, bildet die Basis für den zweiten Änderungswunsch. Dies ist nicht gleich sichtbar in der Stückliste des Änderungsauftrages, aber sobald der Status von "validiert" zu "in Kraft" geändert werden soll, merkt Odoo, dass bereits eine Änderung stattgefunden hat und benennt die Aktion von "Änderungen anwenden" um zu "Umbasierung anwenden", was die “neue alte” Stückliste austauschen würde.

Zudem erscheint der Reiter "Vorherige Stücklistenänderungen des Änderungsauftrags", der vorher nicht zu sehen war:

Ein Beispiel für mehr Klarheit: Eine Stückliste enthält bisher einen Fahrradrahmen und zwei Räder. Mitarbeiter A schlägt vor, noch einen Sattel hinzuzufügen. Mitarbeiter B einen Lenker. Beide schlagen es gleichzeitig vor und haben jeweils zum Zeitpunkt ihrer Idee die zweiteilige Stückliste mit Rahmen und Rädern vorliegen. Zuerst wird der Sattel von A bewilligt und sobald nun der Vorgesetzte auch den Lenker von B bewilligen will, sieht er den Knopf "Umbasierung" und den neuen Reiter mit vorherigen Änderungen. Dort sieht er, dass vorher bereits ein Sattel hinzugefügt wurde. Er bestätigt "Umbasierung anwenden" und die neue Stückliste mit dem Sattel, aber bisher ohne Lenker, wird gültig (und entsprechend die Stücklistenrevision hochgesetzt). Der Auftrag hat nach wie vor den Status "Validiert" und der Button oben heißt nun wieder "Änderungen anwenden", welcher bei Betätigen dann noch den Lenker hinzufügt und die neue Stückliste abschließt mit nunmehr 4 Teilen.

5. Weitere nützliche Tipps

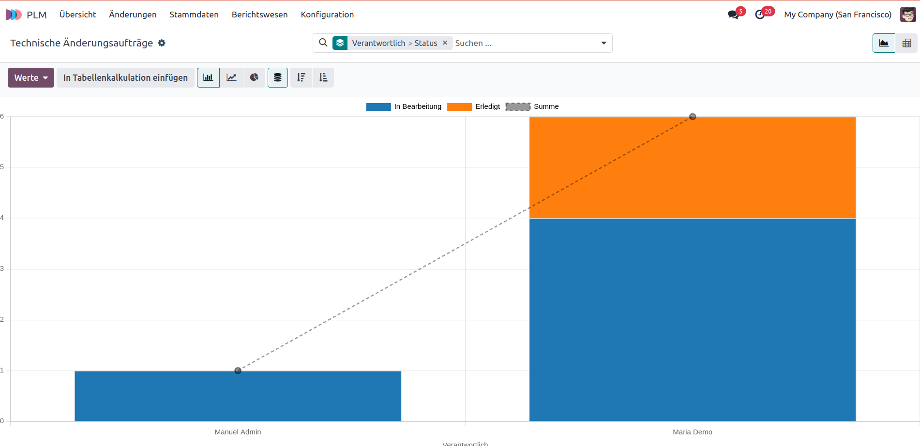

Sie wollen eine Prämie ausloben, für die Mitarbeiter, die die meisten Vorschläge eingebracht haben und benötigen dafür Infos?

Nutzen Sie hierfür das Berichtswesen des Moduls. Sie können sich Statistiken sowohl als Pivot als auch als graphische Auswertung anzeigen lassen:

Und falls Ihnen die beiden Standardmöglichkeiten “Stücklistenaktualisierungen” und “Produkt-Neueinführung” nicht ausreichen, können Sie unter “Konfiguration” auch neue Änderungsauftragsarten ergänzen. Odoo ermöglicht zudem, die Phasen flexibel festzulegen. Standard sind “Neu”, “In Bearbeitung”, “Validiert” sowie “In Kraft”, aber Ergänzungen, Löschungen und Umbenennungen sind möglich. Außerdem kann pro Auftragsart eine E-Mail Adresse vergeben werden, sodass die Mitarbeiter Vorschläge auch durch Mails einreichen können.

6. Unterschiede von Odoo 16 zu Odoo 17

Das Beispiel in diesem Blogartikel ist basierend auf Odoo 17. In Odoo 16 ist für das Einbringen von Änderungen aus der Fertigung heraus nicht die App "Qualität" notwendig, da in dieser Version für eine Änderung kein dazugehöriger Qualitätskontrollpunkt gewählt werden muss:

PLM Verbesserungsvorschlag in Odoo 16

Dies löst den entsprechenden PLM aus.

In V17 muss mit heutigem Stand dafür das Modul “Qualität” ebenfalls installiert sein, weil ein Qualitätspunkt (der einem konkreten Arbeitsschritt zugewiesen sein muss) für den Änderungsvorschlag gewählt werden muss.

7. Fazit

Mit den richtigen Einstellungen unterstützt Odoo Ihr Ideenmanagement, spart Kosten und motiviert zudem Ihre Mitarbeiter. Auch wenn Odoo 17 in der Verbindung von Fertigung zu Produktlebenszyklus noch in der Perfektionierung ist, fördern die Beteiligungsmöglichkeiten der Fertigungsmitarbeiter in Odoo nichtsdestotrotz das Ideenmanagement in Ihrer Firma.

Sie sind auf der Suche nach einem effizientem PLM-System? Kontaktieren Sie jetzt unsere PLM Experten, um das Beste aus Ihrer Produktion zu machen.

Quellen: www.odoo.com, www.theprojectgroup.com, www.forcam.com

Zusammenarbeit im Product Lifecycle Management (PLM)